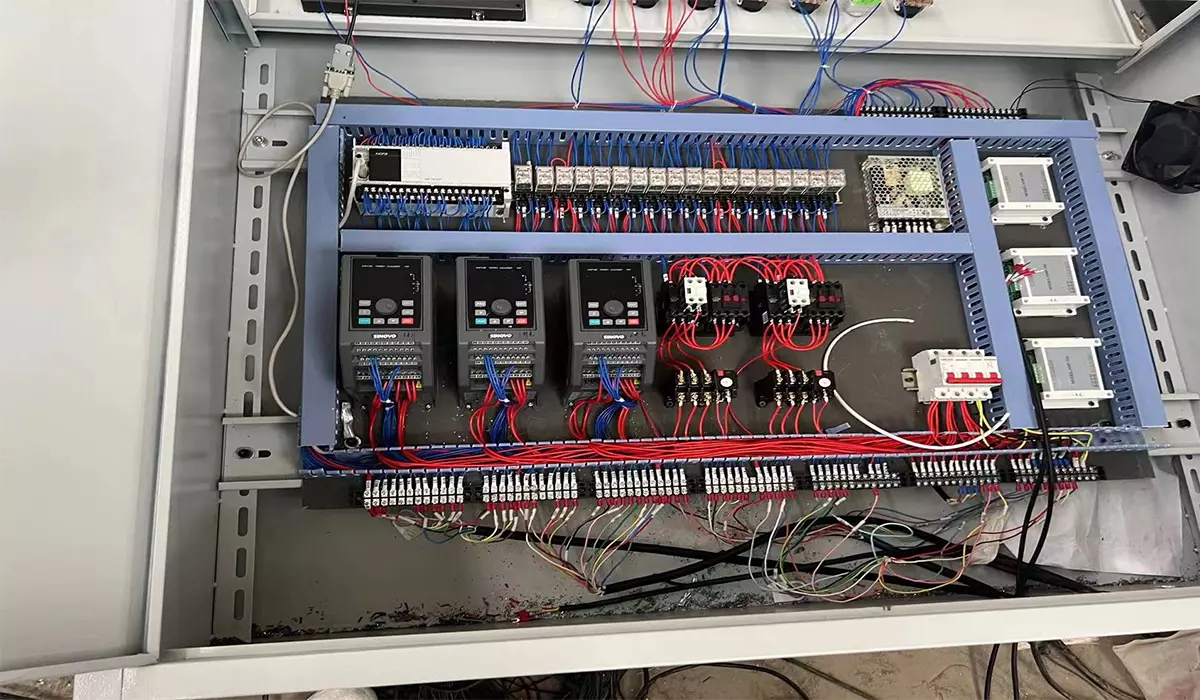

Variable Frequency Drives (VFDs) are essential components in motor control systems, providing efficient speed control and energy savings in various industrial and commercial applications. However, there are specific situations where the addition of an energy consumption brake unit becomes necessary to enhance the functionality and performance of the VFD.

1.High Inertia Loads:

Overcoming Inertia:

In applications with high inertia loads, such as large fans or heavy machinery, the motor may struggle to decelerate the load effectively without additional braking assistance. An energy consumption brake unit provides the necessary braking torque to quickly and safely bring the load to a stop, preventing overspeed and potential damage to the equipment.

Enhanced Control:

By incorporating an energy consumption brake unit, VFDs gain greater control over the deceleration process, allowing for precise and efficient stopping of high-inertia loads. This ensures smooth operation and reduces wear and tear on mechanical components, ultimately prolonging the lifespan of the equipment.

2.Rapid Deceleration Requirements:

Quick Cycle Times:

In applications where rapid deceleration is required to meet production cycle times or safety standards, a standard VFD may not provide sufficient braking capabilities. An energy consumption brake unit offers fast and reliable braking performance, enabling the system to achieve the desired deceleration rates efficiently.

Emergency Stop Scenarios:

In emergency stop scenarios, such as in conveyor systems or automated machinery, immediate deceleration is critical to prevent accidents and ensure personnel safety. An energy consumption brake unit enables the VFD to respond rapidly to emergency stop commands, reducing the risk of collisions or injuries.

3.Regenerative Braking Applications:

Energy Recovery:

In certain applications, such as elevators or cranes, where the load undergoes frequent deceleration and acceleration cycles, regenerative braking can be employed to recover energy and improve overall system efficiency. An energy consumption brake unit allows the VFD to harness the kinetic energy of the decelerating load and convert it into electrical energy, which can be fed back into the power supply or utilized elsewhere in the system.

Reduced Energy Costs:

By implementing regenerative braking with an energy consumption brake unit, VFDs can reduce energy consumption and lower operating costs. The recovered energy can offset power consumption during acceleration phases, resulting in significant energy savings over time and a more sustainable operation.

4.Compliance with Safety Regulations:

Safety Standards:

In industries where compliance with safety regulations is mandatory, such as in automotive manufacturing or aerospace applications, the use of energy consumption brake units may be required to meet specific safety standards. These units provide an additional layer of safety by ensuring controlled and reliable deceleration of equipment, minimizing the risk of accidents or equipment damage.

Risk Mitigation:

By integrating energy consumption brake units into VFD systems, manufacturers can mitigate risks associated with equipment malfunction or operator error. The enhanced braking capabilities provided by these units enhance overall system reliability and safety, reducing the likelihood of costly downtime or workplace accidents.

There are several scenarios where a Variable Frequency Drive (VFD) may require an energy consumption brake unit to enhance its performance and functionality. Whether dealing with high inertia loads, rapid deceleration requirements, regenerative braking applications, or compliance with safety regulations, the addition of an energy consumption brake unit provides numerous benefits, including improved control, energy recovery, and enhanced safety. By carefully assessing the specific needs of the application and integrating the appropriate braking solution, VFD systems can achieve optimal performance, efficiency, and reliability in various industrial and commercial settings.

VFD: When Does a Variable Frequency Drive Need an Energy Consumption Brake Unit

Variable Frequency Drives (VFDs) are essential components in motor control systems, providing efficient speed control and energy savings in various industrial and commercial applications. However, there are specific situations where the addition of an energy consumption brake unit becomes necessary to enhance the functionality and performance of the VFD.

1.High Inertia Loads:

Overcoming Inertia:

In applications with high inertia loads, such as large fans or heavy machinery, the motor may struggle to decelerate the load effectively without additional braking assistance. An energy consumption brake unit provides the necessary braking torque to quickly and safely bring the load to a stop, preventing overspeed and potential damage to the equipment.

Enhanced Control:

By incorporating an energy consumption brake unit, VFDs gain greater control over the deceleration process, allowing for precise and efficient stopping of high-inertia loads. This ensures smooth operation and reduces wear and tear on mechanical components, ultimately prolonging the lifespan of the equipment.

2.Rapid Deceleration Requirements:

Quick Cycle Times:

In applications where rapid deceleration is required to meet production cycle times or safety standards, a standard VFD may not provide sufficient braking capabilities. An energy consumption brake unit offers fast and reliable braking performance, enabling the system to achieve the desired deceleration rates efficiently.

Emergency Stop Scenarios:

In emergency stop scenarios, such as in conveyor systems or automated machinery, immediate deceleration is critical to prevent accidents and ensure personnel safety. An energy consumption brake unit enables the VFD to respond rapidly to emergency stop commands, reducing the risk of collisions or injuries.

3.Regenerative Braking Applications:

Energy Recovery:

In certain applications, such as elevators or cranes, where the load undergoes frequent deceleration and acceleration cycles, regenerative braking can be employed to recover energy and improve overall system efficiency. An energy consumption brake unit allows the VFD to harness the kinetic energy of the decelerating load and convert it into electrical energy, which can be fed back into the power supply or utilized elsewhere in the system.

Reduced Energy Costs:

By implementing regenerative braking with an energy consumption brake unit, VFDs can reduce energy consumption and lower operating costs. The recovered energy can offset power consumption during acceleration phases, resulting in significant energy savings over time and a more sustainable operation.

4.Compliance with Safety Regulations:

Safety Standards:

In industries where compliance with safety regulations is mandatory, such as in automotive manufacturing or aerospace applications, the use of energy consumption brake units may be required to meet specific safety standards. These units provide an additional layer of safety by ensuring controlled and reliable deceleration of equipment, minimizing the risk of accidents or equipment damage.

Risk Mitigation:

By integrating energy consumption brake units into VFD systems, manufacturers can mitigate risks associated with equipment malfunction or operator error. The enhanced braking capabilities provided by these units enhance overall system reliability and safety, reducing the likelihood of costly downtime or workplace accidents.

There are several scenarios where a Variable Frequency Drive (VFD) may require an energy consumption brake unit to enhance its performance and functionality. Whether dealing with high inertia loads, rapid deceleration requirements, regenerative braking applications, or compliance with safety regulations, the addition of an energy consumption brake unit provides numerous benefits, including improved control, energy recovery, and enhanced safety. By carefully assessing the specific needs of the application and integrating the appropriate braking solution, VFD systems can achieve optimal performance, efficiency, and reliability in various industrial and commercial settings.

VFD: When Does a Variable Frequency Drive Need an Energy Consumption Brake Unit

continue reading

Related Posts

Variable Frequency Drives (VFDs) are essential components in modern motor control systems, allowing precise control over motor speed and torque. […]

In today’s industrial control market, the utilization of variable frequency technology to facilitate motor speed control has emerged as a […]

Variable Frequency Drives (VFDs) play a crucial role in controlling the speed of motors in various industrial applications. However, in […]