Product Detail

SD90 series general type of frequency inverter is based on EH600A, it is based on vector quantization V/F control technology, covering EH600A series all software functions, and use the latest generation of Infineon IGBT module. Product appearance, internal hardware and structure design are more reasonable, so that the machine reliability is higher. SD90 series inverter are widely used in textile, metal, plastic, wood, chemical, ceramics and other ancillary equipment; Heating, water supply, central air conditioning, air compressor and other energy-saving projects.

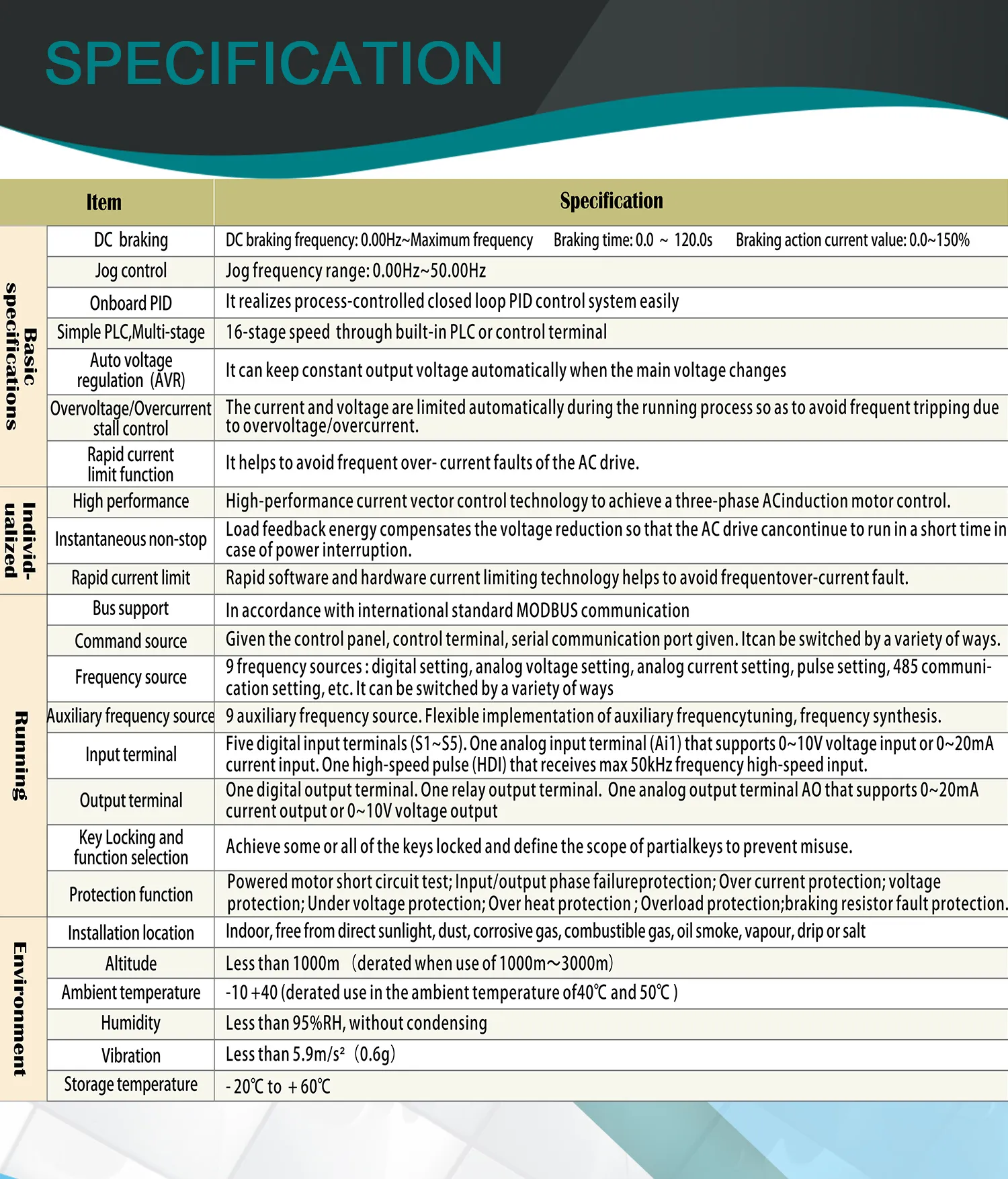

Product Specification:

|

ltem

|

Specification

|

|

|

High performance

|

Vector V/F control technology to achieve a three-phase AC induction motor control

|

|

|

Non stop Function

|

Load feedback energy compensates the voltage reductionso that the AC drive can continue to run in a short timein case of power interruption.

|

|

|

Rapid current limiting

|

Rapid software and hardware current limiting technologyhelps to avoid frequent over-current fault.

|

|

|

Timing Control

|

Timing control function: Set the time range: 0.0Min – 6500.0Min

|

|

|

Bus Support

|

Comply with international Modbus communication

|

|

|

Command source

|

Operation panel reference, control terminal reference. serial communication port referencehese can switch through various ways

|

|

|

Frequency source

|

Seven frequency sources: digital setting, analog voltage setting,analog current setting, pulse setting, serial port settings.These can switch through various ways

|

|

|

Auxiliary frequency source

|

Seven auxiliary frequency sources.which can flexible achieve auxiliary frequency fine-tuning and synthesis frequency

|

|

|

Input terminal

|

Five digital input terminals S1 – S5,1 analog input terminals Ai1.which supports 0-10V or 0- 20mA current inputi high-speed pulse input terminal HDl.which can receive the highest 50KHz frequency pulse input.

|

|

|

Output terminal

|

One digital output terminal, 1 relay output terminal,1 analog output terminal AOsupport 0 ~ 20mA current output or 0 -~ 10V voltage output

|

|

|

Key lock and selection function

|

Achieve some or all of the keys locked and define the scope of partial keys to prevent misuse.

|

|

|

Protection function

|

Powered motor short circuit test: Input/output phase failure protection.

Over current protection. oltage protection. Under voltage protection. Over heat protection : Overload protection. braking resistor fault protection. |

|

|

Installation location

|

Indoor free from direct sunlight. dust corrosive gascombustible gas, oil smoke, vapour, drip or salt

|

|

|

Altitude

|

Less than 1000m ( derated when use of 1000m – 3000m )

|

|

|

Ambient temperature

|

-10°C – + 40°C ( derated when use in ambient temperature of 40°C – 50°C )

|

|

|

Humidity

|

Less than 95%RH without condensation

|

|

|

Vibration

|

Less than 5.9m/s² ( 0.6g )

|

|

|

Storage temperature

|

-20°C – +60°C

|

|

Carrier frequency: 2.0kHz~10kHz. According to the load characteristics, automatic adjust carrier frequency

Input frequency resolution: Digital setting:0.01Hz Analog setting: Max. frequency×0.025%

Control mode: 0:V/F control 1:Vector control

Speed range:1:50 1Hz/150% Rate torque

Torque boost:Manual torque boost 0.1%~20.0%

V/F curve Four modes: Line, Multi-point , Square V/F curve, V/F separation

Line or S-curve Acc/Dec mode : four kinds of Acc/Dec times. Range of Acc/Dec Time : 0.0~6000.0s

DC brake frequency: 0.00Hz~Max frequency brake time:0.0s~36.0s brake current: 0.0%~100.0%

Simple PLC Multi-speed running: 16-speed operating through built-in PLC or control terminal

Onboard PID: It realizes process-controlled closed loop control system easily

Automatic voltage regulation (AVR): It can keep constant output voltage automatically when the main voltage changes

Overvoltage stall control: The current and voltage are limited automatically during the running process so as to avoid frequent tripping due to overvoltage/overcurrent.

Rapid current limit: It helps to avoid frequent over-current faults of the AC Drive