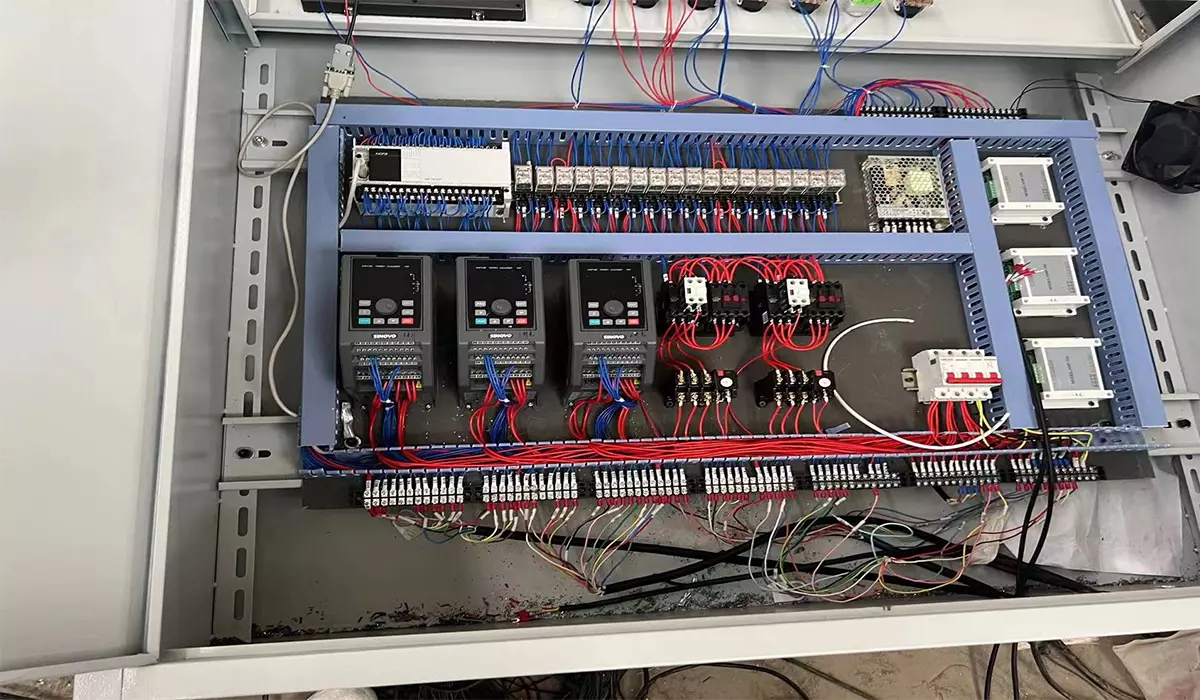

Variable Frequency Drives (VFDs) play a crucial role in controlling the speed of motors in various industrial applications. However, in some cases, VFDs can introduce interference that affects the accuracy and reliability of flow meters used for measuring fluid flow rates.

1.Understanding VFD Interference:

Electrical Noise:

VFDs generate electrical noise as a byproduct of their operation, which can interfere with the signals produced by flow meters. This noise can manifest as voltage spikes, harmonics, and electromagnetic interference, leading to inaccurate flow readings and measurement errors.

Frequency Interference:

The frequency modulation characteristic of VFDs can coincide with the operating frequency of flow meters, causing interference and signal distortion. This interference can result in erratic flow measurements and challenges in maintaining process control and efficiency.

2.Identification of Interference Sources:

Conducting Site Surveys:

Performing site surveys to identify potential sources of interference is essential. Assess the proximity of VFDs to flow meters and other sensitive equipment, as well as the routing of power and signal cables, to determine the likelihood of interference.

Monitoring Signal Integrity:

Utilize signal monitoring equipment to assess the integrity of flow meter signals in the presence of VFD operation. Analyze signal waveforms and characteristics to identify abnormalities or deviations that may indicate interference from VFDs.

3.Mitigation Strategies:

Shielding and Grounding:

Implement shielding and grounding measures to minimize the impact of electrical noise on flow meter signals. Install shielded cables for signal transmission and ensure proper grounding of equipment to reduce the effects of electromagnetic interference.

Filtering and Isolation:

Deploy filters and isolation devices to attenuate electrical noise and harmonics generated by VFDs. Use line reactors, ferrite cores, or dedicated noise filters to suppress interference and maintain signal integrity in flow meter circuits.

Signal Conditioning:

Apply signal conditioning techniques to preprocess flow meter signals before they reach data acquisition systems or controllers. Signal conditioning modules can filter out noise, amplify weak signals, and enhance the accuracy and reliability of flow measurements.

4.Communication Protocol Selection:

Opt for Digital Communication:

Consider utilizing digital communication protocols, such as Modbus or Ethernet, for interfacing between VFDs and flow meters. Digital communication offers improved noise immunity and error correction capabilities, reducing the likelihood of interference-related issues.

Isolate Analog Signals:

Where analog signal transmission is unavoidable, employ isolation techniques to separate flow meter signals from VFD-induced noise. Isolation amplifiers or optocouplers can provide galvanic isolation and prevent noise coupling between VFDs and flow meters.

5.Regular Maintenance and Monitoring:

Periodic Calibration:

Schedule regular calibration and maintenance checks for flow meters to ensure accuracy and reliability. Verify flow meter performance under typical operating conditions and make adjustments as necessary to compensate for any interference-related effects.

Continuous Monitoring:

Implement continuous monitoring of flow meter signals and VFD operation to detect anomalies and address potential interference issues proactively. Utilize data logging and analysis tools to track performance trends and identify recurring patterns indicative of interference.

Dealing with interference from Variable Frequency Drives (VFDs) on flow meters requires a systematic approach involving identification, mitigation, and ongoing monitoring. By understanding the sources of interference, implementing appropriate shielding and filtering measures, selecting suitable communication protocols, and conducting regular maintenance, operators can minimize the impact of VFD-induced interference and ensure accurate flow measurement in industrial processes. With careful attention to detail and proactive management, interference-related challenges can be effectively addressed, enabling reliable and precise flow monitoring in diverse applications.

VFD: Dealing with Interference of Variable Frequency Drives on Flow Meters

Variable Frequency Drives (VFDs) play a crucial role in controlling the speed of motors in various industrial applications. However, in some cases, VFDs can introduce interference that affects the accuracy and reliability of flow meters used for measuring fluid flow rates.

1.Understanding VFD Interference:

Electrical Noise:

VFDs generate electrical noise as a byproduct of their operation, which can interfere with the signals produced by flow meters. This noise can manifest as voltage spikes, harmonics, and electromagnetic interference, leading to inaccurate flow readings and measurement errors.

Frequency Interference:

The frequency modulation characteristic of VFDs can coincide with the operating frequency of flow meters, causing interference and signal distortion. This interference can result in erratic flow measurements and challenges in maintaining process control and efficiency.

2.Identification of Interference Sources:

Conducting Site Surveys:

Performing site surveys to identify potential sources of interference is essential. Assess the proximity of VFDs to flow meters and other sensitive equipment, as well as the routing of power and signal cables, to determine the likelihood of interference.

Monitoring Signal Integrity:

Utilize signal monitoring equipment to assess the integrity of flow meter signals in the presence of VFD operation. Analyze signal waveforms and characteristics to identify abnormalities or deviations that may indicate interference from VFDs.

3.Mitigation Strategies:

Shielding and Grounding:

Implement shielding and grounding measures to minimize the impact of electrical noise on flow meter signals. Install shielded cables for signal transmission and ensure proper grounding of equipment to reduce the effects of electromagnetic interference.

Filtering and Isolation:

Deploy filters and isolation devices to attenuate electrical noise and harmonics generated by VFDs. Use line reactors, ferrite cores, or dedicated noise filters to suppress interference and maintain signal integrity in flow meter circuits.

Signal Conditioning:

Apply signal conditioning techniques to preprocess flow meter signals before they reach data acquisition systems or controllers. Signal conditioning modules can filter out noise, amplify weak signals, and enhance the accuracy and reliability of flow measurements.

4.Communication Protocol Selection:

Opt for Digital Communication:

Consider utilizing digital communication protocols, such as Modbus or Ethernet, for interfacing between VFDs and flow meters. Digital communication offers improved noise immunity and error correction capabilities, reducing the likelihood of interference-related issues.

Isolate Analog Signals:

Where analog signal transmission is unavoidable, employ isolation techniques to separate flow meter signals from VFD-induced noise. Isolation amplifiers or optocouplers can provide galvanic isolation and prevent noise coupling between VFDs and flow meters.

5.Regular Maintenance and Monitoring:

Periodic Calibration:

Schedule regular calibration and maintenance checks for flow meters to ensure accuracy and reliability. Verify flow meter performance under typical operating conditions and make adjustments as necessary to compensate for any interference-related effects.

Continuous Monitoring:

Implement continuous monitoring of flow meter signals and VFD operation to detect anomalies and address potential interference issues proactively. Utilize data logging and analysis tools to track performance trends and identify recurring patterns indicative of interference.

Dealing with interference from Variable Frequency Drives (VFDs) on flow meters requires a systematic approach involving identification, mitigation, and ongoing monitoring. By understanding the sources of interference, implementing appropriate shielding and filtering measures, selecting suitable communication protocols, and conducting regular maintenance, operators can minimize the impact of VFD-induced interference and ensure accurate flow measurement in industrial processes. With careful attention to detail and proactive management, interference-related challenges can be effectively addressed, enabling reliable and precise flow monitoring in diverse applications.

VFD: Dealing with Interference of Variable Frequency Drives on Flow Meters

continue reading

Related Posts

Variable Frequency Drives (VFDs) are essential components in modern motor control systems, allowing precise control over motor speed and torque. […]

In today’s industrial control market, the utilization of variable frequency technology to facilitate motor speed control has emerged as a […]

Variable Frequency Drives (VFDs) are essential components in motor control systems, providing efficient speed control and energy savings in various […]