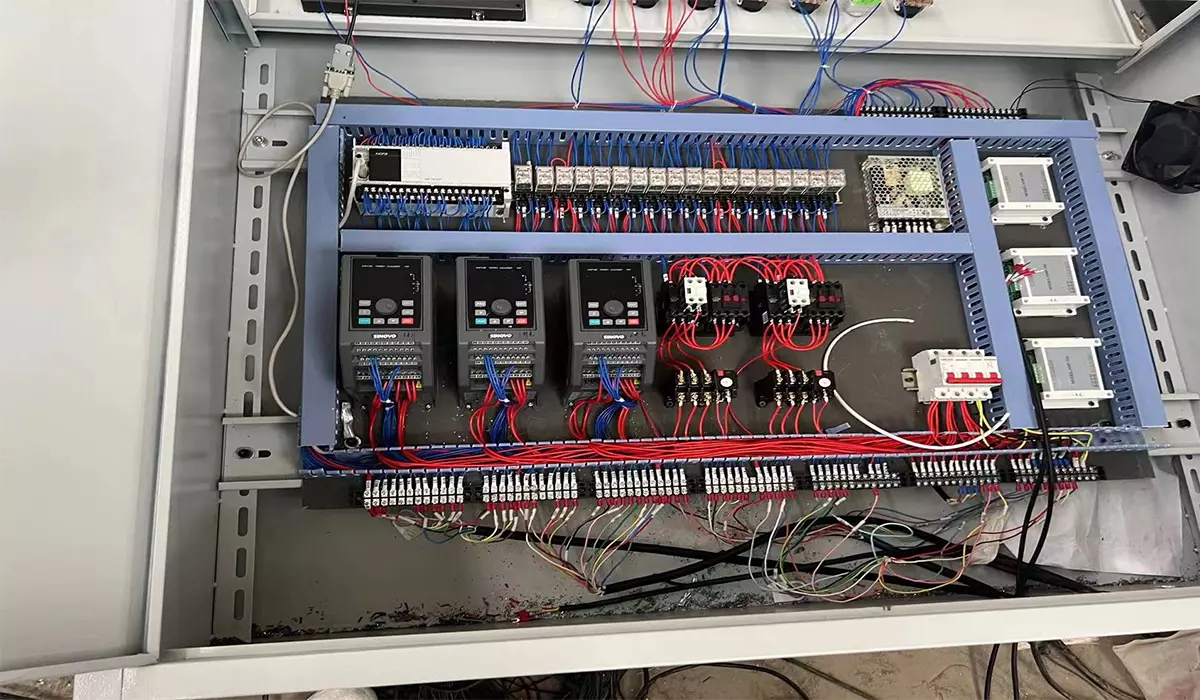

When a variable frequency drive (VFD) requires cleaning due to dust accumulation, several important considerations must be taken into account to ensure safe and effective maintenance.

1.Power Off and Lockout/Tagout:

Safety First:

Before initiating any cleaning procedures, ensure that the VFD is powered off and safely locked out/tagged out to prevent accidental startup. Follow established lockout/tagout procedures to eliminate the risk of electrical shock or injury during maintenance activities.

Verify Power Isolation:

Double-check that power to the VFD is completely isolated by using a voltage tester or multimeter to confirm zero voltage presence. This precaution is crucial for personnel safety and prevents potential damage to the VFD components during cleaning.

2.Use Proper Cleaning Tools and Supplies:

Non-Abrasive Materials:

Select cleaning tools and supplies that are non-abrasive and specifically designed for electronic equipment. Avoid using harsh chemicals, abrasive brushes, or abrasive cloths that could damage the sensitive components of the VFD.

Compressed Air or Vacuum:

Use compressed air or a vacuum with a soft brush attachment to gently remove dust and debris from the exterior surfaces of the VFD. Ensure that the air pressure is regulated to prevent damage to electronic components and avoid blowing dust further into the device.

3.Focus on Ventilation and Cooling:

Clear Air Vents:

Pay particular attention to the air vents and cooling fans of the VFD, as these areas are prone to dust accumulation and can affect the device’s thermal management system. Use compressed air or a vacuum to clear any obstructions and ensure proper airflow for cooling.

Check Internal Components:

If necessary, remove the cover of the VFD to access internal components for cleaning. Use caution and follow manufacturer guidelines to avoid damaging sensitive electronics. Inspect the internal circuitry, cooling fans, and heat sinks for any signs of dust buildup or obstruction.

4.Inspect for Damage or Wear:

Visual Inspection:

While cleaning the VFD, perform a visual inspection of all components for signs of damage, wear, or corrosion. Look for loose connections, overheating indicators, or any other abnormalities that may indicate potential issues requiring further attention.

Tighten Loose Connections:

Check for loose electrical connections, terminal screws, and wire harnesses within the VFD. Tighten any loose connections using appropriate tools and techniques to ensure reliable electrical connections and prevent future problems.

5.Follow Manufacturer Guidelines:

Consult User Manual:

Refer to the manufacturer’s user manual or technical documentation for specific cleaning instructions and recommended maintenance procedures. Follow the guidelines provided by the manufacturer to ensure proper care and maintenance of the VFD.

Schedule Regular Maintenance:

Establish a routine maintenance schedule for cleaning and inspecting the VFD to prevent dust buildup and ensure continued operation. Regular maintenance helps prolong the lifespan of the VFD and minimizes the risk of unexpected failures or malfunctions.

Cleaning a variable frequency drive (VFD) requires careful attention to safety, proper tools, and adherence to manufacturer guidelines. By following the key considerations outlined in this article, maintenance personnel can effectively remove dust and debris from the VFD, inspect for damage or wear, and ensure optimal performance and reliability. Regular cleaning and maintenance are essential for prolonging the lifespan of the VFD and minimizing the risk of downtime or equipment failure in industrial and commercial applications.

PDF: Key Considerations for Cleaning a Variable Frequency Drive

When a variable frequency drive (VFD) requires cleaning due to dust accumulation, several important considerations must be taken into account to ensure safe and effective maintenance.

1.Power Off and Lockout/Tagout:

Safety First:

Before initiating any cleaning procedures, ensure that the VFD is powered off and safely locked out/tagged out to prevent accidental startup. Follow established lockout/tagout procedures to eliminate the risk of electrical shock or injury during maintenance activities.

Verify Power Isolation:

Double-check that power to the VFD is completely isolated by using a voltage tester or multimeter to confirm zero voltage presence. This precaution is crucial for personnel safety and prevents potential damage to the VFD components during cleaning.

2.Use Proper Cleaning Tools and Supplies:

Non-Abrasive Materials:

Select cleaning tools and supplies that are non-abrasive and specifically designed for electronic equipment. Avoid using harsh chemicals, abrasive brushes, or abrasive cloths that could damage the sensitive components of the VFD.

Compressed Air or Vacuum:

Use compressed air or a vacuum with a soft brush attachment to gently remove dust and debris from the exterior surfaces of the VFD. Ensure that the air pressure is regulated to prevent damage to electronic components and avoid blowing dust further into the device.

3.Focus on Ventilation and Cooling:

Clear Air Vents:

Pay particular attention to the air vents and cooling fans of the VFD, as these areas are prone to dust accumulation and can affect the device’s thermal management system. Use compressed air or a vacuum to clear any obstructions and ensure proper airflow for cooling.

Check Internal Components:

If necessary, remove the cover of the VFD to access internal components for cleaning. Use caution and follow manufacturer guidelines to avoid damaging sensitive electronics. Inspect the internal circuitry, cooling fans, and heat sinks for any signs of dust buildup or obstruction.

4.Inspect for Damage or Wear:

Visual Inspection:

While cleaning the VFD, perform a visual inspection of all components for signs of damage, wear, or corrosion. Look for loose connections, overheating indicators, or any other abnormalities that may indicate potential issues requiring further attention.

Tighten Loose Connections:

Check for loose electrical connections, terminal screws, and wire harnesses within the VFD. Tighten any loose connections using appropriate tools and techniques to ensure reliable electrical connections and prevent future problems.

5.Follow Manufacturer Guidelines:

Consult User Manual:

Refer to the manufacturer’s user manual or technical documentation for specific cleaning instructions and recommended maintenance procedures. Follow the guidelines provided by the manufacturer to ensure proper care and maintenance of the VFD.

Schedule Regular Maintenance:

Establish a routine maintenance schedule for cleaning and inspecting the VFD to prevent dust buildup and ensure continued operation. Regular maintenance helps prolong the lifespan of the VFD and minimizes the risk of unexpected failures or malfunctions.

Cleaning a variable frequency drive (VFD) requires careful attention to safety, proper tools, and adherence to manufacturer guidelines. By following the key considerations outlined in this article, maintenance personnel can effectively remove dust and debris from the VFD, inspect for damage or wear, and ensure optimal performance and reliability. Regular cleaning and maintenance are essential for prolonging the lifespan of the VFD and minimizing the risk of downtime or equipment failure in industrial and commercial applications.

PDF: Key Considerations for Cleaning a Variable Frequency Drive

continue reading

Related Posts

Variable Frequency Drives (VFDs) are essential components in modern motor control systems, allowing precise control over motor speed and torque. […]

In today’s industrial control market, the utilization of variable frequency technology to facilitate motor speed control has emerged as a […]

Variable Frequency Drives (VFDs) play a crucial role in controlling the speed of motors in various industrial applications. However, in […]